3D printing is mooted by some as the saviour of design – but, having witnessed the technology’s performance over the years, Richard Prime believes it is actually a critically flawed process that still needs some work …

Columns from me have been a little sparse of late. Sadly the chores of putting food on a plate so I may nourish my body have left inspiration a little crude and hard to explore. Yet the bile on one particular subject, namely 3D printing, has caused digestion problems – so, in order that I nourish once more, this short rant must be written.

"Cast your mind back to the days of the early computers, the ones you used that made you throw your fists and curse at the sky. You’re close to the tedium and unpredictability of a process which is nowhere near to threatening anything made by a skilled hand."

Much like the previous version I constructed last year, following Milan’s furniture fair and its ‘big (non) topic’ concerning the unfair treatment of designers (boo hoo), this new post-Milan shadow of doubt has to fall on this year’s ‘big thing’.

In fact, let’s get this straight once and for all – 3D printing is not a new thing. It was first run out in the 80s. It was then highlighted in the early 00s by a few magazines including one of my old outlets, and then was dropped in an interview by the (then) head of the London Design Festival last year.

Let’s clarify first that there are a number of different techniques being bundled into this loosely-rolled umbrella of a term as well. So for starters, the commentators need to specify – think a bit more ‘designery’, instead of that glory headline, 3D Printing: The Next Industrial Revolution.

There are two main strains which the media like to group together – 3D printing and its big brother, Selective Laser Sintering (SLS). While both are additive techniques to create structure, they’re a world apart.

SLS was the first technique which came into the public eye – technical, and capable of flowing, seamless sculptural shapes. The name SLS derives from how it works as a manufacturing process – harnessing a precise design from a CAD rendering to selectively sinter thin layers of ceramic or glass (now woods and metals also) powder with a laser. It works in layers, with each layer being dropped lower into the bed of powder before the machine sets off again.

In Milan, my chums DFTS Factory collaborated with Swedish super-designers Claesson Koivisto Rune on a bracelet which used the technology to create thousands of tiny links already joined together during the process of manufacture.

It’s SLS which is the groundbreaker here – a process capable of producing moving joints or elements of a design which are already connected as they are made. Knee joints, for example. 3D printing on the other hand is far from the groundbreaker people are saying it is. A ballbreaker, perhaps …

Cast your mind back to the days of the early computers, the ones you used that made you throw your fists and curse at the sky. You’re close to the tedium and unpredictability of a process which is nowhere near to threatening anything made by a skilled hand.

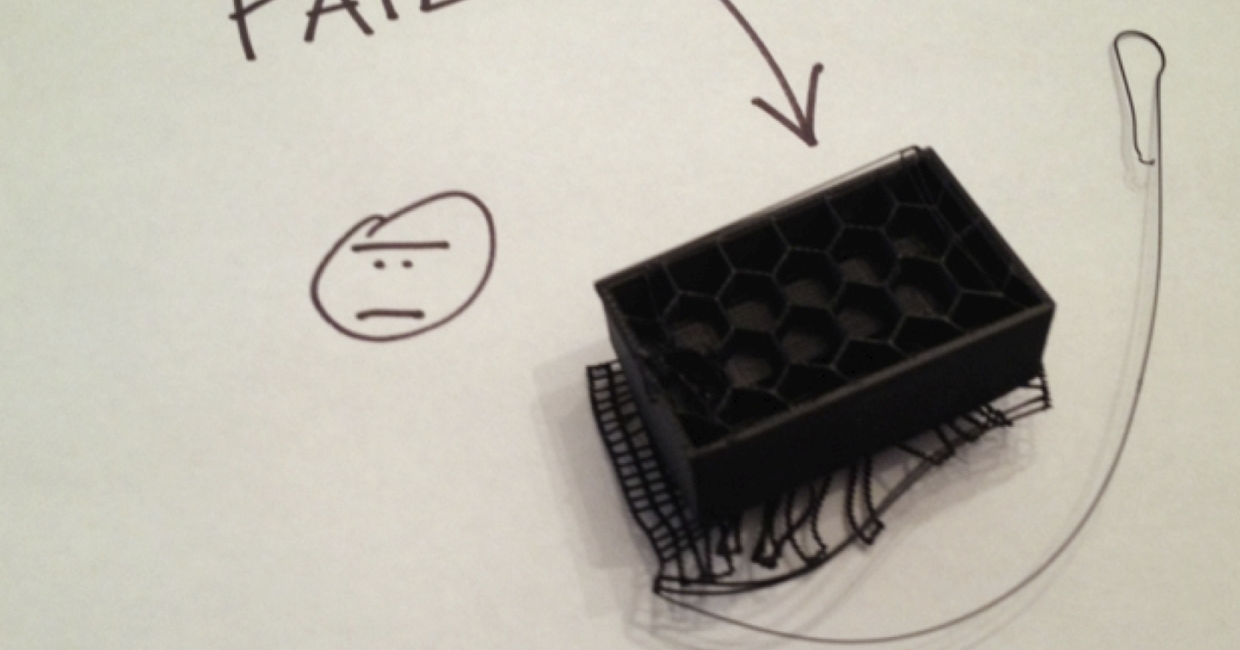

At a recent panel meeting for Dutch Oversight, a new trend forecast I’m making focusing on The Netherlands’ unique design approach, I had the pleasure of watching the technicians at one of the better-known 3D printing facilities faff for about for an hour and a half while a Makerbot spluttered uncontrollably, wasting metres of material as it failed spectacularly to make a cylinder which could have been milled in minutes to a much higher standard. Apparently the machine was suffering a loss of heat. Makernot!

Everyone is apparently very concerned about what will happen when the 3D files for designs get pirated or stolen. I’d not be so worried – there’s not a 3D printing machine in existence which has the capability to mass produce anything other than a blob while simultaneously rendering the user gripped by uncontrollable rage. Even with all the good or bad intent in the world, Joe Bloggs is unlikely to create the downfall of a designer and craftsman, even if they wanted to.

Richard Prime is the founder of Oversight, an independent colour and trend forecasting agency based in Stockholm. Oversight offers a new form of trend and forecast advice, geared around each client’s unique set of demands and drawing on a wide range of source material from across the globe.