Technology is paving the way for new approaches to product marketing, and businesses are fast discovering the benefits of tools such as 3D modelling. The five winners of this year’s edition of The Furniture Awards – Sealy UK, Wiemann, Hartman UK, Parker Knoll, ALF Uno – were given the opportunity to have their star product rendered in all its photorealistic glory, courtesy of creative digital agency, Orbital Vision. Furniture News checked in to see how the project was coming along …

In every corner of the industry, new technology is making processes faster and more efficient. In Long Eaton, creative agency Orbital Vision focuses on the development of new marketing solutions, offering a full suite of sector-specific services – the pinnacle of which is enVision, a digital platform which enables users to create photorealistic 3D models of their products.

The benefits – to both manufacturers and retailers – of developing marketing materials through enVision are manifold, explains Orbital’s creative director, Rob Whotton, who is nearing the end of a process which will see The Furniture Awards winners’ star products brought to life in all their (digital) glory …

What does Orbital do?

Orbital is a creative digital agency, with over a decade of experience of working in the furniture industry. As a company we provide a range of services such as brochure design, websites, photography, video and brand guidance to many of the industry’s leading brands.

An Orbital render featuring ALF Uno’s Fusello table

More recently Orbital has been busy converting its knowledge and experience into the digital world. A significant investment in new tech has provided Orbital with the means to deliver ground-breaking 3D and virtual reality assets to manufacturers and retailers alike, maintaining the company’s progress in delivering every asset associated with bespoke-built websites with full ecommerce capabilities.

How do you go about creating a product render?

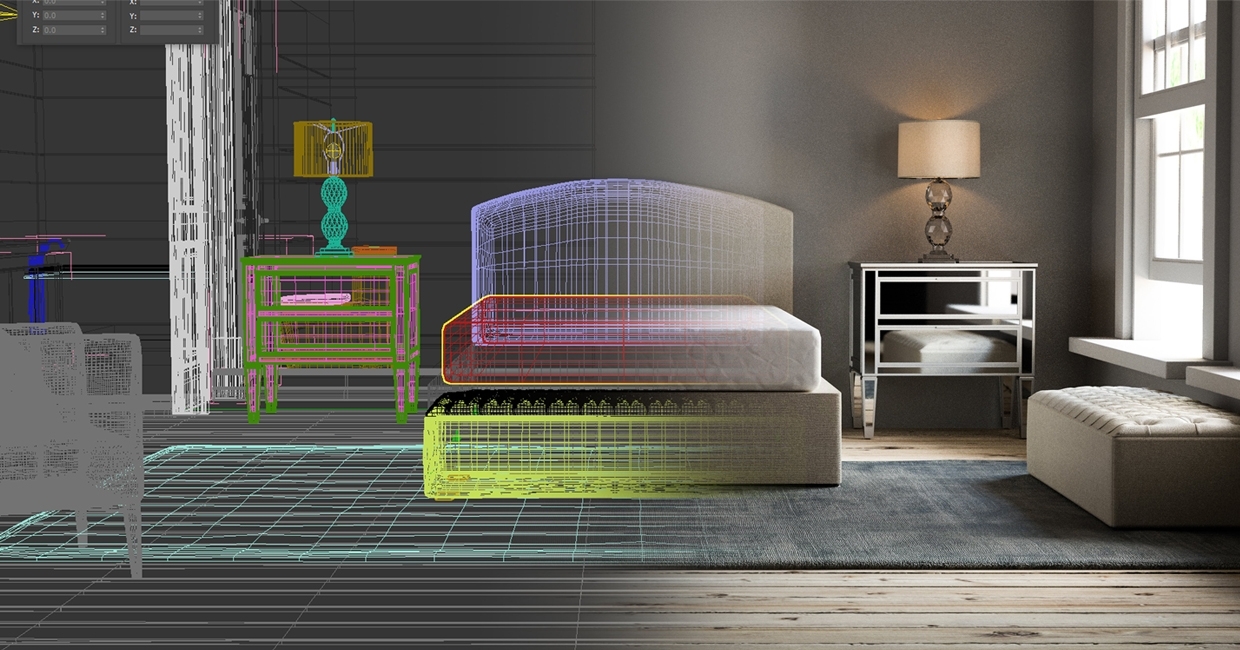

Firstly, we either collect reference imagery and overall sizes from the client, or we go and photograph and measure the products in person. Using that imagery, we build all the furniture in a piece of software called 3ds Max.

The building stage is probably the most time-consuming part of the job, as we spend a lot of time getting every piece of detail spot-on – including all the little imperfections which make all the difference when it comes to a build looking real or fake.

An Orbital render featuring Hartman UK’s Julia resin chair

Once we have built the furniture, we render these out as a white-out, so the client can sign off the overall shapes (the reason we don’t apply any fabric is so they can focus purely on the shape).

Once the builds are signed off, the next step is mapping. This is where we set up the product so fabric can be applied, and we dictate how it sits on the frame. Next, we look closely at the fabric – for us to get the best results we treat the fabrics as a separate job, and how we build the fabric is dependent on the type we’re dealing with. For instance, we will photograph most simple cottons – but with more complex fabrics that are made up of different layers and weaves, we will actually build them in 3D.

An Orbital render featuring Parker Knoll’s Hoxton, from Collection 150

This is the same for velvets. It is impossible to photograph a velvet properly because of how the material reacts to light – it can look light from one angle and dark from another – so we create all our velvets in 3D. This, I feel, is where we truly stand apart from our competitors, as we spend the time perfecting the fabrics so they look real once wrapped on our 3D builds.

Now we have our product built and mapped, this can be rendered out in every different fabric option, at any camera angle (even 360°s). But for most, the next step is to situate their product in a roomset. Like any photoshoot, we start by putting together a moodboard of what look we want to achieve, and which accessories to use and colour scheme to go with. From here, we build everything from the ground up, unique to that client.

An Orbital render featuring Sealy UK’s Activsleep

One of the benefits is that clients can use the same roomset again for their next project, by simply changing out the accessories, walls and floors to make it look like a completely new room.

Finally, there’s the rendering stage. All our projects are set up to batch render, so at the click of a button we can render an entire line of products in a full fabric range of different colours. Everything is rendered in high resolution, so can be used in print, PoS, online and social media marketing to really bring it to life.

What are the benefits of creating marketing assets in this manner?

Photoshoots are quickly becoming a thing of the past – slow turnaround, expensive, and relatively inflexible. With a 3D render, you can make all the changes you want without any extra time or money. And if your product changes, or if you have a selection of fabrics available, all of that can be created and corrected in a 3D model in no time at all.

An Orbital render featuring Wiemann’s Monaco wardrobe

Your products can even be altered before they are created. Manufacturing prototypes traditionally can be expensive, but with 3D rendering, a product can be created from a mere sketch, and can be altered or redesigned in days. And, if you’re creating a whole new range but only have a design for one of the products, you can just leave it to the graphic designers to create 3D prototypes of the remaining products in the range.

How did you find working with this year’s winners of The Furniture Awards?

Personally, I have enjoyed the variety of what the award winners bring, and the different types of furniture we’ve been able to create. It’s also been a great opportunity for us to introduce our 3D services and show them an alternative to the traditional photoshoot.

Watch this space for further information about how Orbital is working with this year's award winners.