Beds or mattresses need to pass ignition resistance tests before manufacturers and suppliers can sell them in the UK, writes SATRA technologist Andrew Munns, who explains the implications of the fire safety regulations for domestic mattresses and upholstered bed bases …

In the UK there are two pieces of legislation specifying flammability requirements that are demanded by UK law: Furniture and Furnishings (Fire) (Safety) Regulations 1988 (as amended in 1989, 1993 and 2010); and the General Product Safety Regulations 2005 (implemented in the UK following the introduction of an EU directive).

Anyone wishing to sell upholstered beds or mattresses in the UK should be aware of these requirements, especially if products are sourced from outside the UK.

There are a number of flammability tests for mattresses and upholstered bed bases which are called up in BS 7177:2008+A1:2011 – Specification for resistance to ignition of mattresses, mattress pads, divans and bed bases. These test the ignition resistance of mattresses, divans and upholstered bed bases to smokers’ materials including cigarettes and matches.

To demonstrate the product is safe (and thereby satisfy the General Product Safety Regulators) the complete construction should pass the Low Hazard rating of BS 7177:2008+A1:2011.

Fillings must comply with the requirements of the Furniture and Furnishings (Fire) (Safety) Regulations 1988 (as amended).

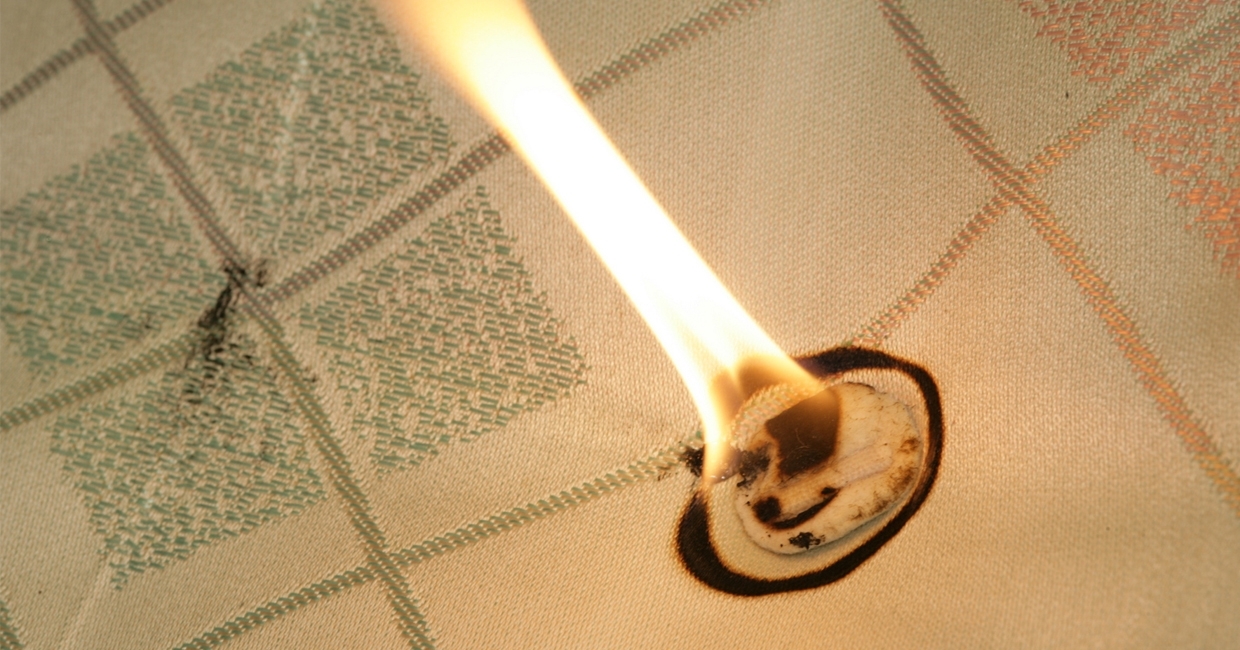

For the former, ignition resistance tests are carried out using a standard smouldering cigarette and simulated match flame. The tests are described in BS EN 597:1995 – Furniture – Assessment of the ignitability of mattresses and upholstered bed bases, parts one and two, respectively.

All of these tests are carried out on a full-size mattress or a model of the mattresses that replicates the make-up of the unit and the surface properties such as tufting, quilt lines and tape edges. Testing involves placing the sources of ignition on all of these surface features.

Fillings used in mattresses and bed bases must meet the same requirements as upholstered furniture. The actual requirements depend on whether it is a single filling or a composite filling.

Where there are single fillings in beds and mattresses, these should pass the relevant ignition resistance tests in the Furniture and Furnishings (Fire) (Safety) Regulations 1988 (as amended). Polyurethane (PU) foam block should meet Schedule 1 Part I. Polyurethane foam crumb should meet Schedule 1 Part II. Rubber latex foam should meet Schedule 1 Part III.

Composite fillings in beds and mattresses should either be tested so every layer of filling meets the requirement for a single filling or the total composite meets Schedule 2 Part IV. Any foam within a composite filling must also meet the single foam filling requirement.

Mattress toppers are treated no differently. The definition of a mattress in this specification is worded in such a way that it includes all items that are slept upon, including mattress pads and toppers, which are often sold to enhance the comfort of a mattress, are usually constructed with a foam or fibre filling or a natural filling, and have an outer cover – although some toppers are just blocks of foam without a cover.

The UK Government holds the view that mattress toppers or mattress pads should be treated in the same way as mattresses. This means that fillings should pass the appropriate ignition tests and the complete item should conform to the specification in BS 7177:2008+A1:2011 at the appropriate level of conformance.

Subsequently, beds and mattresses must be correctly labelled. The label content, format and design is specified in BS 7177:2008+A1:2011, and should be positioned so it is easily seen.

It should be noted that a requirement for the testing of both faces of a mattress has now been included (unless they are identical). If the tickings on each side are different, or if the underlying fillings are different, both sides have to be tested (a bed manufacturer will often provide a winter and a summer surface on a mattress).

Where previously it was a recommendation, the repeat testing of mattresses and the frequency of these tests is now a requirement, and compliance with BS 7177 requires that the item carries the correct label. BS 7177:2008+A1:2011 recommends repeat testing at suitable intervals: one unit tested every six months when fewer than 400 units are produced per month; one per 2400 units for unit production between 44-2400 per month; and one per month when more than 2400 units are produced per month.

Full compliance with BS 7177:2008+A1:2011 at all levels involves labelling and repeat testing at set intervals during production.

SATRA’s furniture testing facility, working to ISO 17025, is an international centre of excellence for furniture and bed testing, training, consultancy and innovation. SATRA has its own in-house flammability test facility capable of testing full-sized mattresses, and can also help manufacturers set up flammability test facilities in its own factories.

SATRA holds regular seminars on the Furniture and Furnishing (Fire) (Safety) Regulations in Kettering, which will next take place on 29th August and 14th November. On 28th November, SATRA will hold a new seminar to discuss relevant requirements and appropriate testing for children’s furniture.